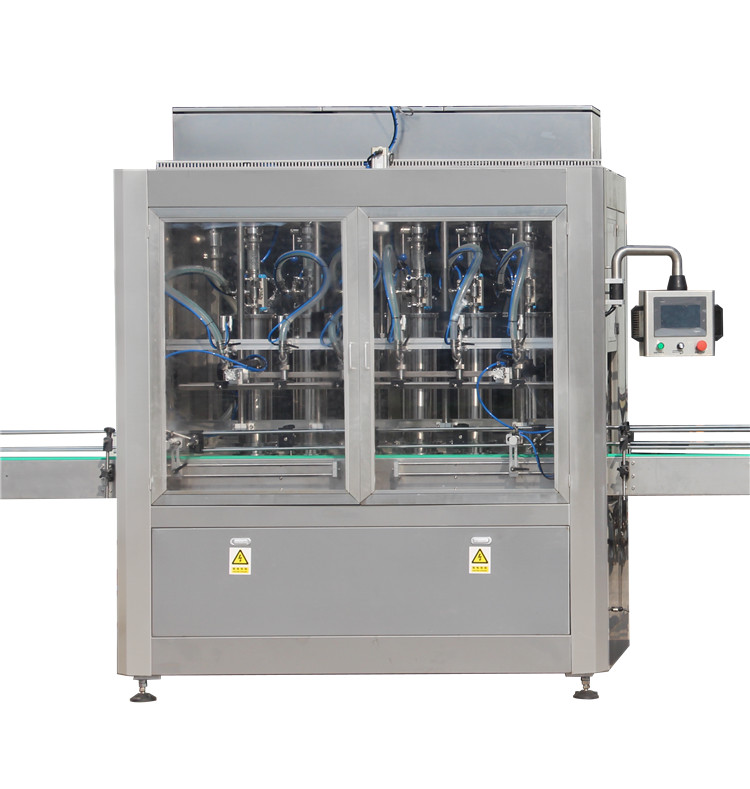

This machine is suitable for all kinds of viscous, non-viscous and corrosive liquids etc. It is widely used in plant oils,

engine oils, chemical liquids, daily chemical liquids etc. This equipment is mechatronics. It is very convenient to

replace bottle samples or liquids. unique design and superior performance. It meets all requirements of customers.

Siemens PLC control system, with control protection function, vacuum leak-proof device, to ensure no leaking situation

during production, electric adjusting for volume system, frequency conversion control and photoelectric control with

German TURCK brand.

Feeding conveyor:

1 easily to change the bottle shape

2. Rise the speed

3. Connect the bottle feeding part

4. Could add the bottle stopping device

5. Air conveyor for the plastic bottle, screw conveyor for the glass bottle

Filling parts

1. No bottle no filling

2. Same filling level of all the bottles, adjustable filling level

3.Filling precision ≤±2mm

4. Vacuum filling method

5. No dropping

Capping part

1.PCO ,plastic cap, metal cap, aluminum cap

2.no bottle no capping

3.two sensor to check, PLC control

4.no full no capping

5. Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

6. All 304stainless steel construction

7. Automatic stop when lack of bottle

8. Automatic caps arranging and feeding, lack of caps automatic feeding

Lamp checker

Clearly to see the filled bottle

Vacuum tank and pump

Because the liquid contains the foam , so not only the valve has the degas feature, we also need the fit the vacuum pump and tank, to suck all the foam from the liquid , and send to the vacuum tank through the vacuum pump

Electrical apparatus

PLC/ transducer/ touch screen: siemens

Contactor/ air switch/ stabilized voltage supply: Schneider

Photo electricity/ proximity switch: Atonics

Cylinder: Air tack

| Filling heads | 4 | 6 | 8 | 10 | 12 | 16 |

| Capacity(1L/bottle/h) | 600-1200 | 1000-1600 | 1600-2200 | 2200-2800 | 2800-3200 | 3200-4000 |

| Filling volume(ml) | 200-1000/ 500-3000/1000-5000 | |||||

| Filling tolerance | ±0.5% | |||||

| Gas pressure(Mpa) | 0.55-0.8Mpa | |||||

| Gas consumption(Mpa) | 0.8 | 1 | 1.2 | 1.4 | 1.6 | 1.8 |

| Motor power(kw) | 1 | 1.2 | 1.4 | 1.6 | 1.6 | 1.8 |