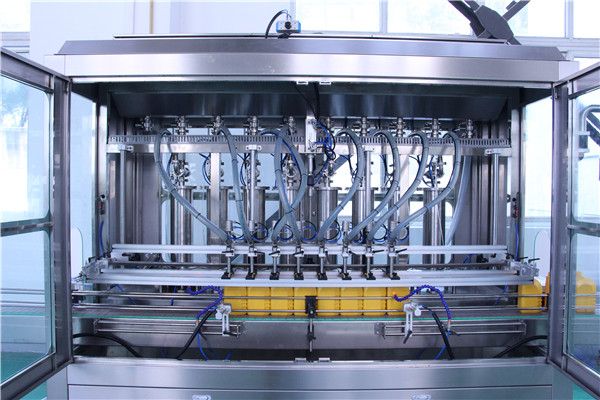

LDP Bottle Chemical Filling Machinery Description:

LDP Bottle Chemical Filling Machinery is newly-designed machine model by our company, which is more advanced than other common anti-corrosive filling machine. LDP bottle chemical filling machine indeed can reach goal that the 100% no leaking.

- Suitable material: Bleach, acid liquid, 84 disinfectant, gel water,toilet cleaner, especially used in the liquid filling of strongly corrosion liquid and cosmetics which can’t touch the metal.

- Contact liquid parts are use anticorrosive non-metallic material and with diving function.

- This Vertical filler is a high-tech filling equipment integrating on the PLC microcomputer programmable control, and photo electricity transduction pneumatic action.

- The LDP bottle chemical filling machinery suits for the filling of different sizes of vessel may change the filling sizes within a few minutes. Short filling circle, high production capacity.

- User may choose the filling volume and decide the filling heads per own production capacity.

- The precision time of the pneumatic valve filling may set to 0.01 second, can make the measurement precision control within ±1%, to decrease unnecessary material loss and enhance the economic efficiency.

- Each filling-head’s measurement may be individually adjusted torealize the same filling measurement.

- The LDP bottle chemical filling machine set such function: having counting program of bottle-feeding, doesn’t fill as there is not bottle or the counting doesn’t attain a predetermined position, can start filling only when the counter records that the bottle number is same as the setting filling number.

- More or less of the filling volume, may initially adjust to the needed Filling volume, then micro adjust, can get the ideal filling measurement precision.